GLULAM

Tried and tested glulam as an alternative to steel and concrete

![[Translate to English:] Brettschichtholz für Schwörer-Holzindustrie [Translate to English:] Brettschichtholz der SchwörerHaus KG im Querschnitt](/fileadmin/_processed_/a/1/csm_Brettschichtholz_b50ad7ea15.jpg)

What is glulam (BSH)?

Glulam (BSH) is an industrially manufactured product for load-bearing constructions.

BSH consists of at least three fibre-parallel glued board lamellas made of softwood, which are connected force-fit to each other at the front end by means of finger-jointing. Dried quality-controlled spruce wood (in accordance with DIN 14081) is used for the production.

The DIN EN 14080 standard is relevant for the production of glulam. The width is determined by the individual lamellas. The maximum permissible slat thickness is 42 mm. The height depends on the number of glued board lamellas. Thus, a large number of standardized cross-sections are available. It can be manufactured in any length by finger-jointing according to DIN EN 14080.

BSH is dimensionally stable, fits perfectly and is therefore easy to process. The surface is planed on four sides and the edges are chamfered.

fields of application

Planning and building with glulam is individual, safe and economical. Glulam-wood is the construction material for advanced and sophisticated constructions and for this reason a sensible alternative to steel and concrete. Glulam-wood is an ideal building material for residential building, old building, redevelopment area and constructive timber construction. The modern glued wood construction method also opens up a wide range of design possibilities for the architect in interior work. Remaining visible constructions create a pleasant atmosphere due to the characteristic appearance and the natural charisma of the wood.

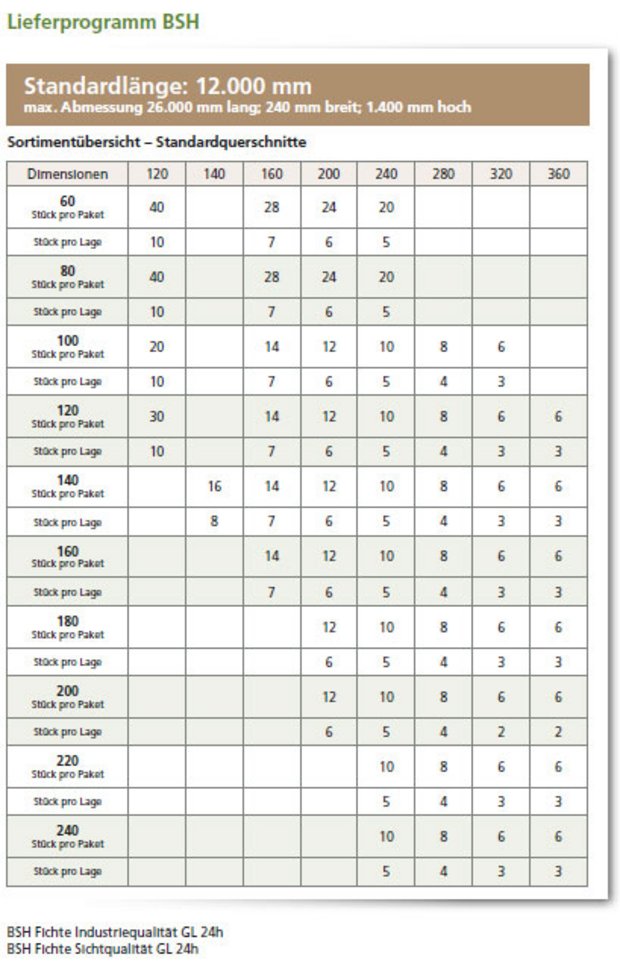

delivery and performance programme

- type of wood: spruce

- stability classes: GL 24h

- quality: visual quality, industrial quality

- length: 12m (special lengths possible, at least 6m, maximal 26m)

- width: maximal 240mm

- height: maximal 1400mm

- slat thickness: 40mm

- surface: 4 sides planed and chamfered

- wood moisture: 12% +/-2%

- gluing: melamine resin, bright glued joint

- packaging: industrial quality – package wrapped / visual quality – single and package wrapped

- impregnation: colourless / yellow (until 13m)

monitoring mark for glulam

The glulam-wood monitoring mark was created by companies producing glulam-wood. The aim of the mark owners is to produce and document quality that goes beyond the requirements of the building authorities. The owners of the mark undertake, among other things, to comply with stricter production requirements, to declare surface quality and to carry out internal and external monitoring of the product well beyond the requirements of DIN EN 14080: 2013.